Industrial Parts Cleaning Faces

The cleaning of industrial parts is widely acknowledged as a key value-adding step in the overall production chain. But new trends – such as Industry 4.0, miniaturization, electromobility, vehicle lightweight design and new or modified manufacturing and coating technologies – pose new challenges for cleaning industrial parts and surfaces.

The story is the same across many industrial sectors: automotive, component supply, mechanical engineering, aviation, precision engineering, medical technology and others. Cleaning machined components and assemblies is essential for preventing quality issues in further downstream processes and for proper functioning of the finished product. Thus, this step is also a major quality factor in staying competitive.

New Trends

In many industries, the main emphasis after machining has been removing particulate contaminants using wet chemical cleaning methods. Removing film-type contaminants has been a priority, notably when preparing parts and surfaces for coating, laser welding, tempering or adhesive bonding. The need for these cleaning steps is unlikely to change in the future. But new trends pose fresh challenges.

For fine-cleaning applications, features such as an electropolished chamber with integral wall flushing help avoid recontamination of the cleaned components by preventing the backflow of dirt or the formation of dirt traps inside the chamber. Image courtesy of Hoeckh Metal Cleaning Systems GmbH

One example is the trend toward ever smaller and more complex parts. Shorter product life cycles, smaller production runs (including one-offs), the use of new materials (typically in lightweight vehicle construction) and new production processes are other examples, not to mention major technical developments, such as electromobility, autonomous driving and the digitization of parts production.

As a result of these developments, wet chemical fine and ultrafine cleaning will become more mainstream, as will alternative cleaning processes, such as CO2 snow blasting. In turn, there will be increased demand for controlled manufacturing environments engineered for cleanliness.

Adaptable Cleaning Systems

Wet chemical cleaning will undoubtedly remain the most common technology. But to prepare for changing market needs and shifting technical demands, facilities must become flexible.

The parts cleaning industry is already anticipating emerging needs by designing plants with built-in adaptability to handle a range of parts and standards of cleanliness, as well as alternative cleaning methods. This means not only installing more efficient ultrasound systems, pressure pumps and filtration systems but incorporating technical developments that enable plant operators to adjust the cleaning parameters to match the specific size and geometry of the parts passing through the system. The ability to quickly and easily swap out cleaning tools, such as spray units, is one such development, along with the separation of cleaning and drying operations in the case of water-based cleaning.

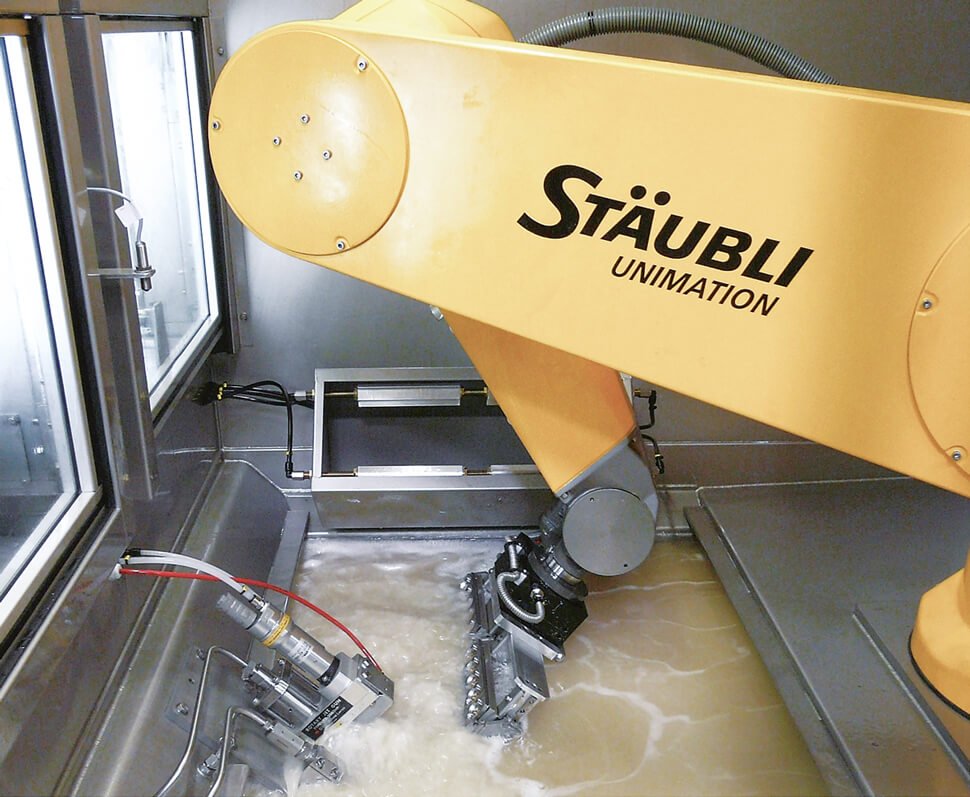

For cleaning individual parts, robots designed and specially sealed for use in cleaning machines enable various processes, such as deburring, spray cleaning and dip cleaning, as well as drying. Image courtesy of Stäubli International AG

To achieve the requisite degree of cleanliness, manufacturers are increasingly turning to fine and ultrafine cleaning processes to remove particulates and surface films. Important factors include the basic design and configuration of the cleaning plant (for example, the number of treatment stations and drying facilities), appropriate process technology (like multifrequency ultrasound), cleaning chemistry and process design. Other technical aspects also need to be considered, including flow optimization, parts carriers, piping, automated conveyors and air management.

Integrated/Adaptive Cleaning

The trend toward intelligent, networked production processes has enabled manufacturers to significantly improve productivity, product quality and flexibility while simultaneously reducing costs. This trend is also driving changes in parts cleaning. For example, fully automated in-line plant solutions that can clean and dry bulk goods, such as screws, and then transport them onward to the next processing stage are already available. Intelligent generators for use in ultrasonic cleaning can now configure themselves and then monitor and optimize their own operation. As a result, the optimal operating frequency can be automatically determined and set before the ultrasonic pulse is triggered.

Continuous monitoring and logging of plant and process parameters in wet chemical cleaning plants is now a common feature. Plants can be equipped with sophisticated instrumentation for continuous in-line monitoring, control and adjustment of cleaning baths. These systems permit accurate documentation of operating parameters during cleaning and can be used to inject additional cleaning agents into the bath as required. The process is fully automated, needing no intervention by a machine operator. Initial solutions to monitor cleaning results in-line are also available. These typically use fluorescence measurement technology to check for the presence of film residue.

Thus far, the use of CO2 snow blasting, laser cleaning or plasma cleaning techniques has been something of a niche specialty when it comes to selectively dry cleaning pre-assembled parts, as well as functional surfaces and designated areas of components prior to adhesive bonding, sealing or laser welding. However, selectively cleaning functional surfaces is set to become more mainstream. Single workpieces present a range of cleaning challenges depending on the component’s use or on the surface cleanliness required for areas destined for further processing. The fact that in-line-capable processes are easily automated has helped drive this trend.

Controlled Environments

Because precision-made components are highly sensitive to particulate contaminants, such as manufacturing residues, dust and fluff, there is a growing need for controlled manufacturing environments engineered for cleanliness. This need also applies to industry sectors where components have traditionally been produced in a “normal” manufacturing environment—for example, automotive, mechatronics, precision/micro-engineering, electronics, hydraulics, glass and medical technology. The objective is to protect the product from harmful particulate contaminants during manufacture and processing. The question is whether that calls for a clean zone, a white room or a clean room.

A clean zone is typically isolated from potentially critical areas—where grinding dust, particulates and other debris are stirred up by people or forklifts—by floor markings, movable partitions or ceiling aprons. A white room is a permanently installed, structurally segregated enclosed space (an area within a room, a separate room or a separate building) where the transfer of staff and materials is organized to avoid contamination and staff is specially trained.

Image courtesy of acp advanced clean production GmbH

Cleaned parts are discharged into the clean room via a material air lock after passing through a fully enclosed cleaning line equipped with its own supply of purified air. Image courtesy of Ecoclean GmbH/UCM AG

Image courtesy of acp advanced clean production GmbH

Cleaned parts are discharged into the clean room via a material air lock after passing through a fully enclosed cleaning line equipped with its own supply of purified air. Image courtesy of Ecoclean GmbH/UCM AG

If the enclosed space is also equipped with clean air technology in the form of high-performance particulate air filters, it is defined as a clean room when a specific ISO air purity class must be achieved or maintained for the manufacturing operation. Clean room air quality has to be checked regularly. So-called particulate traps are available for measuring the ambient cleanliness of clean zones and white rooms.

The main technical difference between a white room and a clean room lies in the type of ventilation and filtration technology used. A minimum positive air space pressure must be maintained in a clean room. The air in the room has to be adjusted and regulated to maintain the specific moisture and temperature conditions required for the product and its processing.

For highly automated production lines, a more compact, practical alternative to the clean room may be the “clean machine concept,” in which the requisite decontamination technology is confined to the actual production line itself. In parts cleaning applications, this solution is used in multistage immersion cleaning systems, where cleaning baths are fully enclosed and equipped with their own supply of purified air. The cleaned parts frequently are discharged into a clean room via a material air lock.

By treating industrial parts cleaning as a key value-added process when producing precision-machined metal parts, manufacturers will be able to tackle new challenges and have a competitive advantage.

- No comments

- 2023-04-10

- 2024-06-28

- 2024-02-26

- 2024-04-09

- 2024-05-11